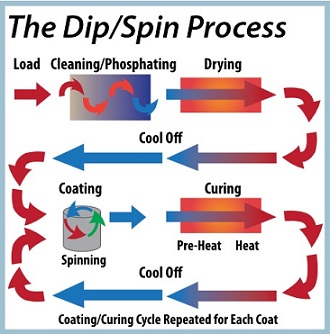

The Dip Spin Process

|

The Dip-Spin process is a bulk application process that applies coatings in a highly effective and economic manner. The process involves placing the pretreated parts in a steel wire mesh basket, dipping the basket in a keg of paint, removing it from the paint and then spinning it to remove the excess paint. The spun off paint is recaptured and reused. The dipping ensures complete coverage while the spinning ensures uniform coating thickness. The desired film thickness is achieved by controlling the paint viscosity, the RPM of spinning, the number of spins and the spin time. Multiple layers of paint may be applied to meet customer specifications. The painted parts are then cured at the prescribed temperature and duration. Curing preforms an important chemical reaction in which cross linkages are formed between the resin molecules in the paint. The curing oven is designed to eliminate parts sticking to one another. Please call us for more information. We will be pleased to arrange a plant tour for you |

|

Contact Us

150 Summerlea Road

Brampton, Ontario

L6T 4X3

Tel: 905 793 4493

Fax: 905 793 9322

Click here for Map.

Certified Applicator of Engineered Coatings

Anti-Friction is the Leading Applicator of Magni's Engineered Coatings in Canada